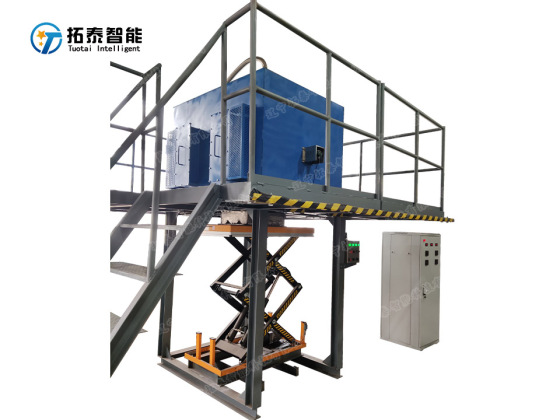

100kg Simulated Pressurized Coke Oven

●100kg simulated pressurized coke oven is one of the models of our company's test coke oven equipment, and it also includes single station, double station, 40kg, 100kg and other design styles.

●100kg simulated pressurized coke oven can be used in the experimental research of conventional and tamping coking to determine the cost-saving coal blending ratio scheme.

- Liaoning Tuotai

- Anshan City, Liaoning Province, China

- Meet the requirements of the buyer

- stock system

- Information

Our company sincerely recruits agents from all over the world, and you are welcome to contact us if you are interested in cooperation. +86-15642202798.

●100kg simulated pressurized coke oven process requirements

1. In order to accurately control the coal blending ratio and coal fineness, and provide stable conditions for coking, the process of crushing first and then blending is selected.

2. The 100kg simulated pressurized coke oven project includes: 100kg electric heating test coke oven, conventional coal blending coking, tamping coal blending coking, coke quenching and supporting coke testing equipment and auxiliary facilities.

3. The process test can carry out conventional coal blending and tamping coal blending coking test research, and can also discuss the appropriate coal blending conditions according to the cold strength index and hot strength index of the generated coke, and infer the economy and possibility of production. It is used to guide production and provide information for the rational use of coal resources.

4. The hearth of the 100kg simulated pressurized coke oven adopts silicon carbide hearth, which has good resistance to rapid cooling and rapid heating, small expansion coefficient, no peeling or cracks in cold or hot state, and long service life. Specific indicators of furnace bricks: refractoriness ≥ 1770 ℃, 0.2Mpa load softening start temperature ≥ 1620 ℃, bulk density 2.50-2.80g/cm3, apparent porosity ≤ 21%, reburning line change (1350 ℃ * 2h) ≤ +0.2 %, normal temperature compressive strength ≥ 85Mpa, thermal shock stability (1100°C water cooling) ≥ 50 times, flexural strength (1100°C*2h) ≥ 20 Mpa, SiC ≥ 86%, Fe2O3≤1.2%.

5. The coking process is electric heating on both sides, coal loading and coke discharge at the bottom, with high degree of automation and easy operation.

6. The computer controls the temperature of the furnace walls on both sides. The error of the constant temperature of the furnace walls on both sides is less than 5°C. It records the temperature of the coke cake center and the furnace top space, with data storage and printing functions.

7. The computer operating system is Win10, the computer starts the control system and modifies the system parameters, and dynamically displays the system operating status and temperature curve.

8. The temperature control adopts the artificial intelligence self-adaptive adjustment algorithm, and there is no overshoot or undershoot in the heating and constant temperature control.

9. The user can set the heating curve arbitrarily, and the programming adopts the method of temperature and time programming, which is convenient and flexible in programming.

10. The 100kg analog pressurized coke oven has the functions of sensor (galvanic couple) disconnection, reverse connection indication and over-temperature alarm.

Our company's 100kg simulated pressurized coke oven is also called 100kg load test coke oven, 100kg coke oven, etc. It is used with coke oven tail gas environmental protection purification device.