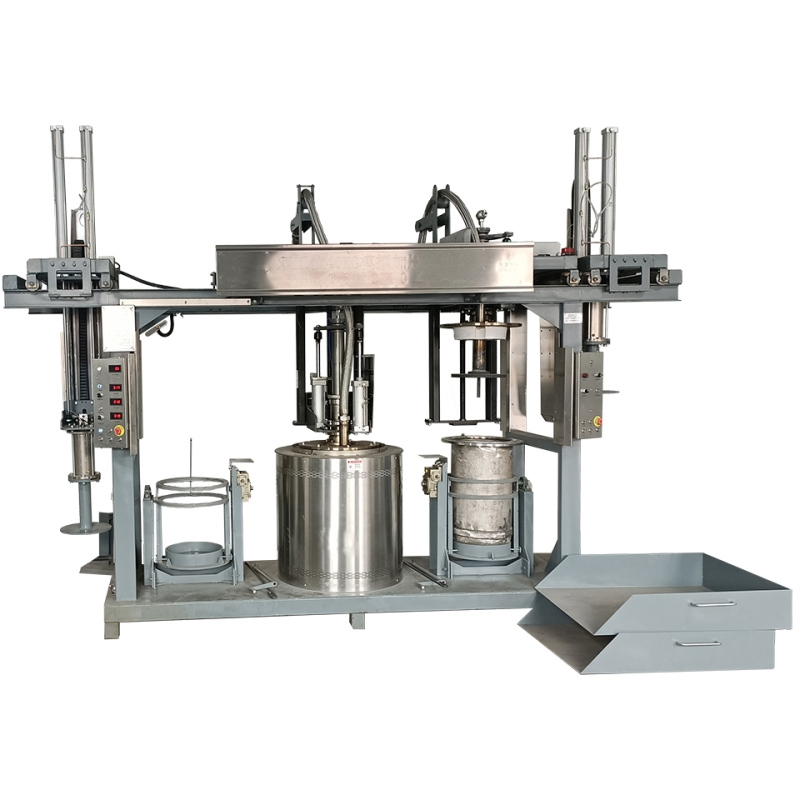

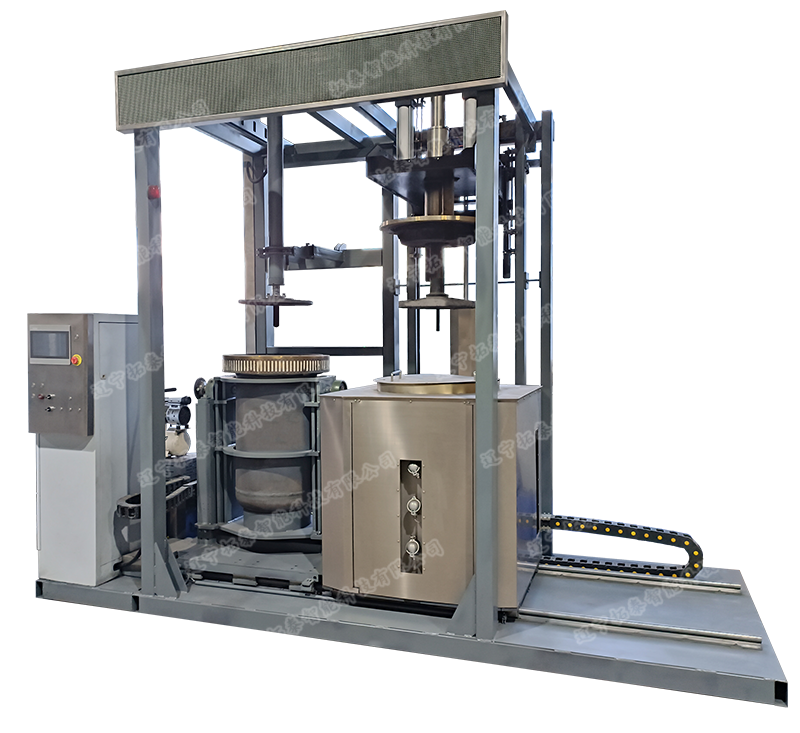

Double Station 40kg Simulated Pressurized Coke Oven

●Double station 40kg simulated pressurized coke oven can realize continuous detection, which has the advantages of saving experiment time and electricity consumption.

●Double station 40kg simulated pressurized coke oven is one of the models of our company's experimental coke oven equipment. In addition, it also includes single-station, double-station, 40kg, 100kg and other design styles.

- Liaoning Tuotai

- Anshan City, Liaoning Province, China

- Meet the requirements of the buyer

- stock system

- Information

Our company sincerely recruits agents from all over the world, and you are welcome to contact us if you are interested in cooperation. +86-15642202798.

●Double-station 40kg simulated pressurized coke oven product introduction

Our company's exclusive patented technology product, the double-station 40kg simulated pressurized coke oven, is also known as the "load test coke oven", which is an upgraded product of the traditional test coke oven. The equipment is used to analyze the coke yield, thermal strength index (CRI, CSR), conventional and ramming coking of blended coal or single coal. Provide test research data for the rational use of coal resources and improvement of coke product quality, which is used to guide and improve production. It can also explore the appropriate coal blending conditions based on the thermal strength index of the generated coke, infer the economy and possibility of production, and provide materials for the rational use of coal resources.

Our company's simulated pressurized coke oven is divided into single-station, double-station, 40kg, 100kg and other design styles. Among them, the double-station style can realize continuous detection, which has the advantages of saving experimental time and electricity consumption.

●Technical features of double station 40kg simulated pressurized coke oven

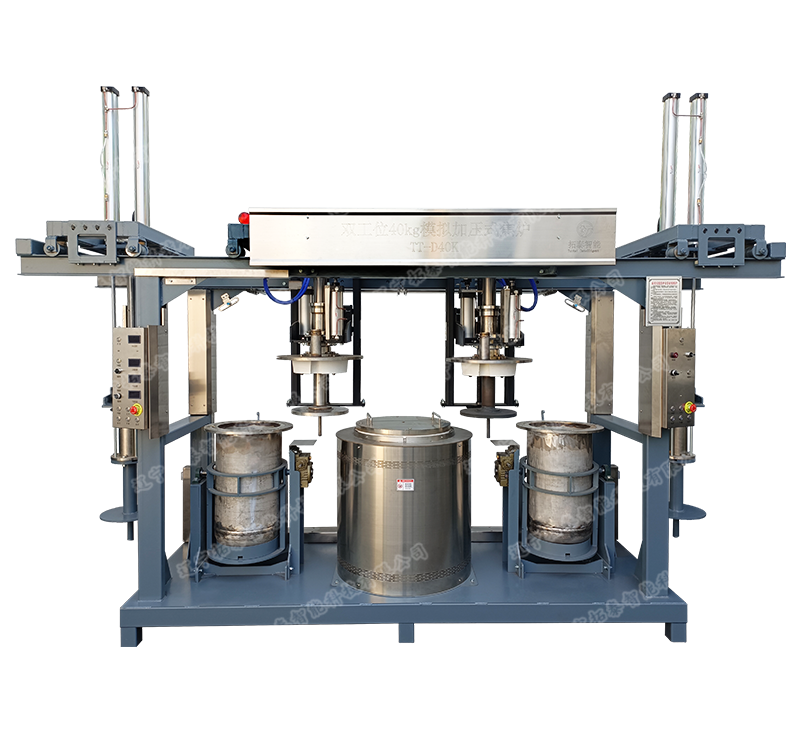

This equipment is a test coke oven between the 200kg semi-industrial test coke oven and the 7kg and 20kg small coke ovens in the laboratory. It not only retains the advantages of the 200kg coke oven, but also overcomes its shortcomings of large coal sample, long coking cycle and high labor intensity. It is an updated product of the 200kg coke oven. At the same time, it also overcomes the shortcomings of narrow oven width and small coke sample in the laboratory 7kg and 20kg small coke ovens. It has a coal loading capacity of ≥40kg at a time, and uses a 1/4 meter kum drum to achieve the purpose of coke identification similar to that of industrial coke ovens (this is difficult to do for 7kg and 20kg coke ovens). The unique structural design and the use of three balanced loads are used by computers and PLCs to achieve precise temperature control of the furnace wall, ensuring that the coking results have a good correlation with the production coke oven. The coke strength index is intuitive and the test results are reproducible. The double furnace design improves the efficiency of equipment use and saves time for continuous testing.

This equipment has the characteristics of tight sealing, more uniform three-stage heating, and simulated pressurization, which is consistent with the CSR value actually produced by large industrial coke ovens.

Our company's double station 40kg simulated pressurized coke oven is also called 80kg load experimental coke oven, 80kg coke oven, double-station coke oven, double station 40kg coke oven, etc. It is used with coke oven tail gas environmental protection purification device.