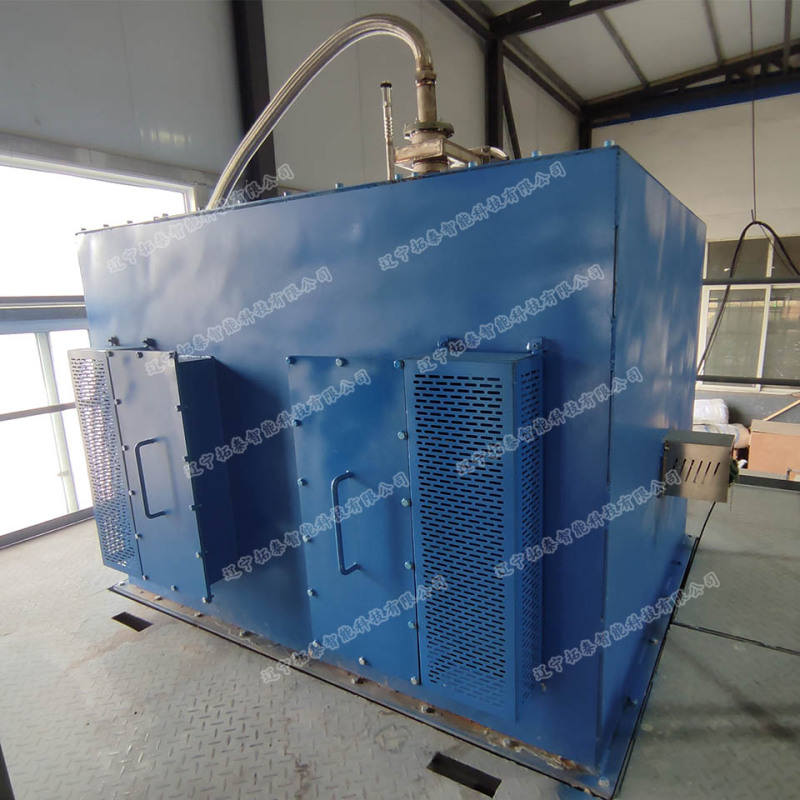

40KG bottom-loaded test coke oven

●The 40KG bottom-mounted test coke oven is equipped with the test coke oven tail gas environmental protection purification device independently developed and produced by our company.

●The 40KG bottom-mounted test coke oven can be lifted and lowered electrically to realize automatic coal feeding and coke discharge.

●The door of the 40KG bottom-mounted test coke oven can be closed quickly and has good sealing performance.

- Liaoning Tuotai

- Anshan City, Liaoning Province, China

- Meet the requirements of the buyer

- stock system

- Information

Our company sincerely recruits agents from all over the world, and you are welcome to contact us if you are interested in cooperation. +86-15642202798.

●Product introduction of 40KG bottom loaded coke oven

The 40KG bottom-loaded test coke oven produced by our company adopts the method of bottom-loading coal and is equipped with an electro-hydraulic lifting device to realize automatic coal loading and coke removal.

The furnace door opens and closes automatically, with good sealing performance. The furnace door can be quickly closed after coke is discharged, which can effectively extend the service life of the furnace bricks and enable the coke oven to run continuously to prepare for the next furnace. The coal loading trolley can easily load coal and remove coke, reducing manual labor.

The furnace structure simulates the single-hole carbonization chamber of an industrial coke oven. The furnace walls on both sides are heated independently. The furnace walls of the carbonization chamber are made of silicon carbide bricks that are resistant to extreme cold and heat to improve heat transfer efficiency and ensure the sensitivity of temperature regulation.

The heating element is a silicon carbon rod, which is arranged on both sides of the furnace wall. The control program executed by the computer controls the temperature of the furnace walls on both sides individually to improve the temperature control accuracy. The core temperature of the coke cake and the temperature of the furnace walls on both sides are collected by the thermocouple and displayed and recorded by the computer.

The test coke oven is also equipped with a coke oven gas combustion treatment system to ensure that coke oven gas emissions meet environmental protection requirements.

●Usage of 40KG bottom loaded coke oven

Analyze the coke yield, thermal strength index (CRI, CSR) of coal blending or single coal, and conduct experimental research on conventional and tamping coking. Provide experimental research data for rational utilization of coal resources and improvement of coke product quality to guide and improve production. We can also explore suitable coal blending conditions based on the thermal intensity index of coke generation, infer the economy and possibility of production, and provide materials for the rational utilization of coal resources.

●Technical parameters of coke oven exhaust environmental protection purification device

supporting 40KG bottom-loaded test coke oven equipment

Coke oven body | Type A equipment dimensions | 4500×3400×3800(mm)(The surrounding maintenance platform contains flue gas purification equipment) | ||

Type B equipment dimensions | 3900×2600×3500(mm)(One-sided maintenance platform contains flue gas purification equipment) | |||

Furnace size | 500×400×550(mm) | Coal density | 0.72t/m3-1.05t/m3 | |

Coal loading capacity | 40-50KG | Fire channel temperature | 1050℃ (Rated up to 1250℃) | |

Heating method | There are 6 silicon carbon rods on each side of the combustion chamber for heating. | Furnace wall material | Composite silicon carbide | |

Furnace wall heating power | 2*20=40KW | Voltage | AC 380V±10% 50Hz | |

Number of phases | Three-phase five-wire | Temperature control method | Computer given, Siemens PLC program control | |

Coking method | Conventional coking, tamping coking | Coke off method | water wet quenching | |

Electronic control system | Control system | Computer, Siemens PLC, 200-Smart | ||

Data processing | Computer remote control, real-time display of temperature control curves, and output of data reports. | |||

The computer program has built-in standard process curves, and users can also call other setting curves. The curve is drawn in real time and displayed on the screen together with the set curve in real time. Users can intuitively see the control results. Real-time display of left and right furnace wall temperatures, center temperature of test coal sample, given temperature, and real-time temperature error. Supports data report function and can be printed as needed. | ||||

Control cabinet | One set | Computer | Lenovo brand | |

Printer | HP Laser | |||

Our company's 40KG bottom-loading test coke oven is also known as 40KG bottom loaded coke oven , Bottom mounted coke oven, bottom mounted coke oven, bottom mounted small coke oven, 40KG traditional coke oven,traditional bottom mounted coke oven.