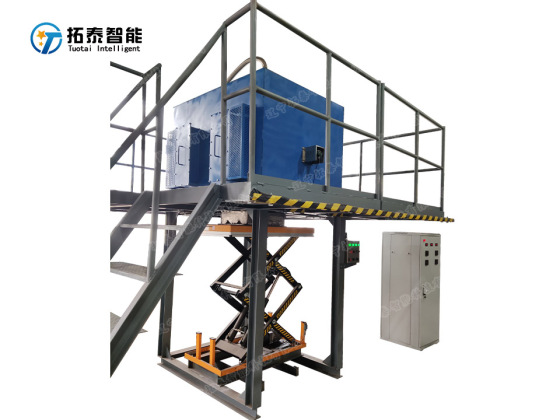

Coke Oven Tail Gas Environmental Protection Purification Device

●The coke oven tail gas environmental protection purification device is the dedicated coke oven tail gas environmental protection purification equipment for the simulated pressurized coke oven of our company.

●The coke oven tail gas environmental protection purification device has good purification effect and high safety factor.

●The coke oven tail gas environmental protection purification device does not require excessive consumables and maintenance.

- Liaoning Tuotai

- Anshan City, Liaoning Province, China

- Meet the requirements of the buyer

- stock system

- Information

Our company sincerely recruits agents from all over the world, and you are welcome to contact us if you are interested in cooperation. +86-15642202798.

●Product introduction of coke oven tail gas environmental protection purification device

Our company is specially designed for coke oven exhaust gas, and the exhaust gas exhausted by coke oven is fully burned in the environmental protection purification device. High-efficiency combustion in the cavity with the best air distribution ratio. The flame has no leakage, and can safely and effectively remove more than 95% of harmful emissions. It solves the problems of similar products such as unsafe flame exposure, no air distribution system, low combustion efficiency, obvious exhaust blackness, and environmental protection emissions that do not meet standards. This product adopts water film impact nozzle to spray intensively, and the contact area is large. Secondary purification of flue gas after combustion achieves the effect of lowering discharge temperature and no smoke. The "high drop" between the combustion chamber and the exhaust outlet is matched with the unique design of the water-sealed valve. When the equipment is unexpectedly powered off, the "natural suction" can also be used to discharge the smoke to the outside. Enlarging the design of the overall combustion chamber, and the integral welding of dense warping pieces greatly reduces the operating temperature of the equipment without excessive consumables and maintenance.

●Advantages of coke oven tail gas environmental protection purification equipment

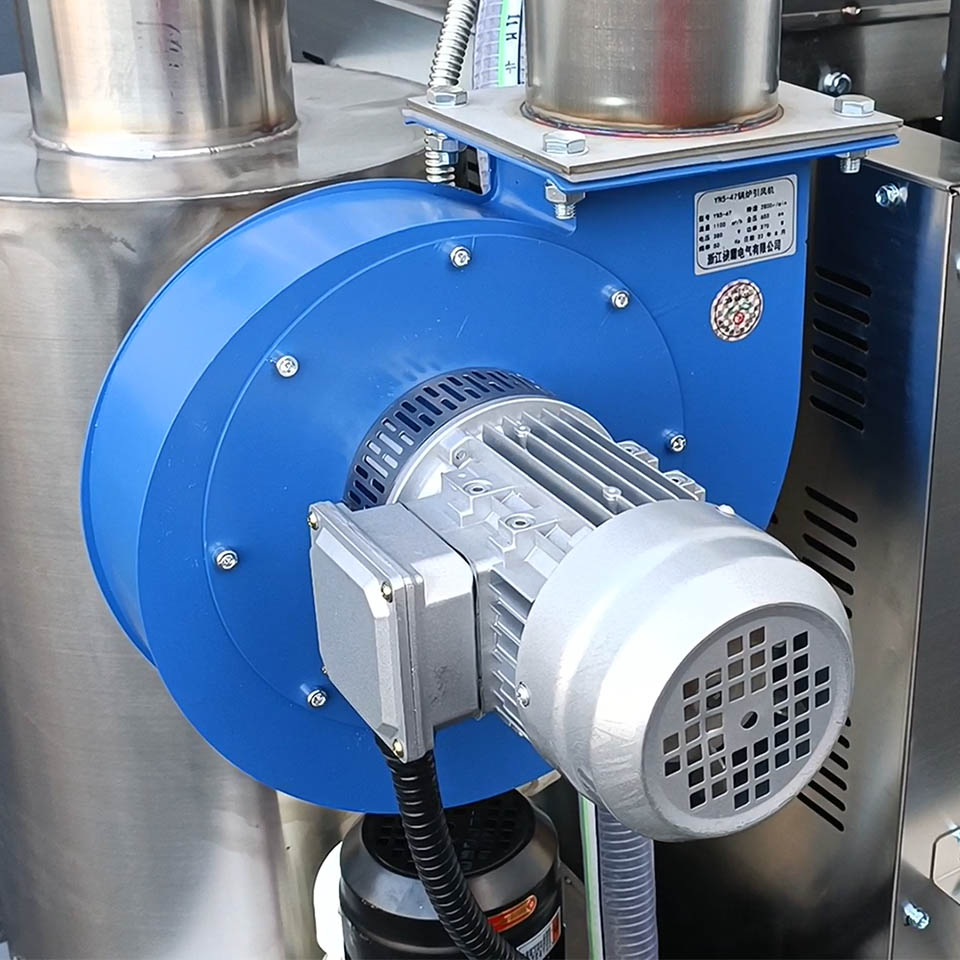

1. The coke oven tail gas environmental protection purification device adopts the high-efficiency combustion method in the cavity with the best air distribution ratio. The flame has no leakage, and can safely and effectively remove more than 95% of harmful emissions. The tail gas induced draft fan adopts a high-temperature fan, which has low noise and large air volume, which improves the stability of equipment operation. At the same time, the water film injection method with a large contact area is adopted to make the secondary purification of the flue gas after combustion achieve the effect of greatly reducing the discharge temperature and no smoke. However, similar products have exposed flames, high temperature, and are unsafe; without an air distribution system, the combustion efficiency is low, the blackness of the exhaust gas is obvious, and the environmental protection emissions do not meet the standards.

2. The combustion chamber of the coke oven tail gas environmental protection purification device has a "high drop" from the tail gas discharge port, and is matched with a unique water-sealed valve design. To ensure that the entire set of coke oven facilities can work safely in the event of an unexpected power failure, and the flue gas can still be discharged to the outside smoothly. However, after the power failure of similar products, the equipment cannot continue to operate, and the smoke will flow back into the room.

3. The coke oven tail gas environmental protection purification device does not require excessive consumables and maintenance. The equipment can operate stably and reliably without using consumables during use. Similar products that adopt the method of condensation purification (chemical production recovery device): the tube condenser is easily blocked, and it is difficult to disassemble and clean. Exhaust gas has a relatively strong odor, and activated carbon and absorbent cotton need to be replaced frequently.

●Technical parameters of coke oven tail gas environmental protection purification device

Voltage power | AC380V 0.75KW | Fan control method | Program and inverter control |

Air distribution fan flow | 600 liters/hour | Pump flow | 3.5 liters/hour |

Flue gas cooling method | Spray cooling | Purification method | Combustion purification |

Combustion chamber cooling method | Natural convection cooling | Tank volume | 50L |

Ignition method | Manual ignition | Tar residue | No residue |

Our company's coke oven tail gas environmental protection purification device is also called coke oven tail gas purification equipment, test coke oven combustion purification device, coke oven tail gas environmental protection purification device, coke oven environmental protection purification equipment, coke oven exhaust gas purification equipment.