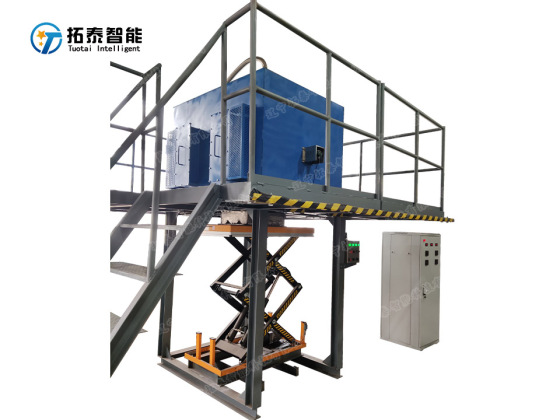

40kg Simulated Pressurized Coke Oven

●40kg simulated pressurized coke oven is equipped with a long-life coal steamer and exhaust gas environmental protection purification device independently developed and produced by our company.

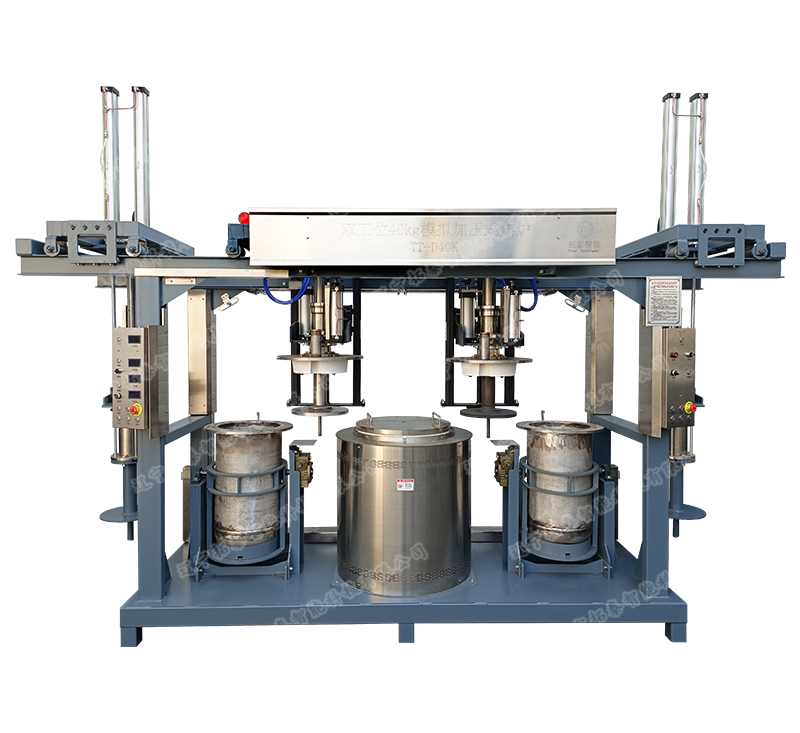

●40kg simulated pressurized coke oven is divided into single station, double station, 40kg, 100kg and other design styles.

- Liaoning Tuotai

- Anshan City, Liaoning Province, China

- Meet the requirements of the buyer

- stock system

- Information

Our company sincerely recruits agents from all over the world, and you are welcome to contact us if you are interested in cooperation. +86-15642202798.

●40kg simulated pressurized coke oven product introduction

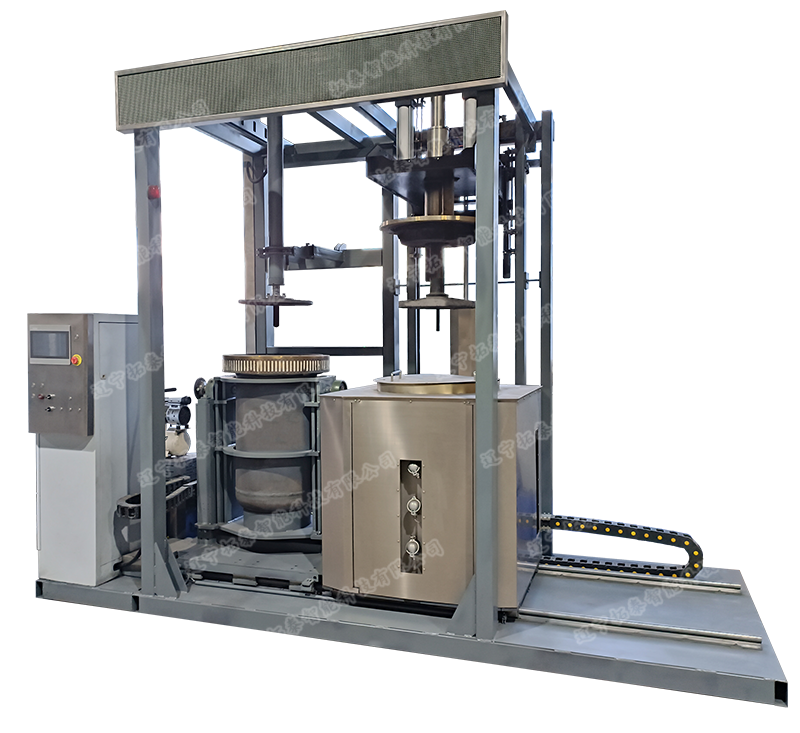

Our company's exclusive patented product 40kg simulated pressurized coke oven, also known as "load test coke oven", is an updated product of the traditional test coke oven. It has the characteristics of tight sealing, more uniform three-stage heating, and can simulate pressurization, which is consistent with the CSR value actually produced by large-scale coke ovens in the industry. Can be used to guide coal blending.

Divided into single-station, double-station, 40kg, 100kg and other design styles, among which the double-station style can realize continuous detection, which has the advantages of saving experimental time and power consumption.

●Technical features of 40kg simulated pressurized coke oven

1. Supporting the long-life coal steamer independently developed and produced by our company, the wall thickness is 10mm, and the service life is more than 6 months under normal use; while the wall thickness of similar products is 5-6mm, and the service life is only 2 months, resulting in higher subsequent use costs . The structure of our company's coal steamer adopts seamless pipe integral molding structure; while the coal steamer of similar products is mostly welded on the side after coiling, and the welding port is easy to open and welded in the later stage, causing experimental tar to overflow, adhere to the furnace wire and burn the furnace. The furnace can be used normally for 2 years, so that the furnace needs to be replaced every 2 months, which increases the additional cost of use.

2. Equipped with the tail gas environmental protection purification device independently developed by our company. High-efficiency combustion in the chamber and post-water film injection are adopted to realize pollution-free discharge. The entire coke oven facility can work safely even if there is a sudden power failure.

3. Three-phase balanced power supply is adopted, and the balance of the power grid is used to precisely control the temperature of the middle and lower sections of the furnace wall at the same time, ensuring a good correlation between the coking result and the coke oven production. And it can be replaced separately to reduce the cost.

●40kg simulated pressurized coke oven technical parameters

Coke oven body | It is composed of base, frame, high temperature dry distillation furnace, lifting and discharging mechanism, flue gas, purification system, tamping system, control system and other series of devices | ||||

Furnace body | Furnace size | φ460*700(㎜) | Heating element | HRE spiral heating body | |

Heating method | Three independent temperature control | Electric heating structure | Spiral inlaid zirconium fiber heating jacket | ||

Heating power | 6KWx3 sections | Operating temperature | ≤1150℃ | ||

Temperature control method | Computer setting, Siemens PLC program control | ||||

Lifting and discharging mechanism | Function | Sample coal steamer and loading device assembly | Lifting method | Lead screw + guide column electric mode | |

Lift height | 800㎜ | Drive mode | screw drive | ||

Tamper | Function | Coal cake density quantitative tamping | Density adjustment range | 0.7-1.05g/㎝3 | |

Tamper base | When the briquettes are tamped, ensure that the coalification container is placed stably | Tamping Control | Pneumatic lifting, air hammer tamping | ||

main control system | Control System | Computer + Siemens PLC (200-Smart) | data processing | Computer remote control, real-time display of temperature control curve, output data report. | |

Our company's 40kg simulated pressurized coke oven is also called loaded coke oven , test coke oven , 40 kg small coke oven , 40kg coke oven , etc. It is used with coke oven tail gas environmental protection purification device.