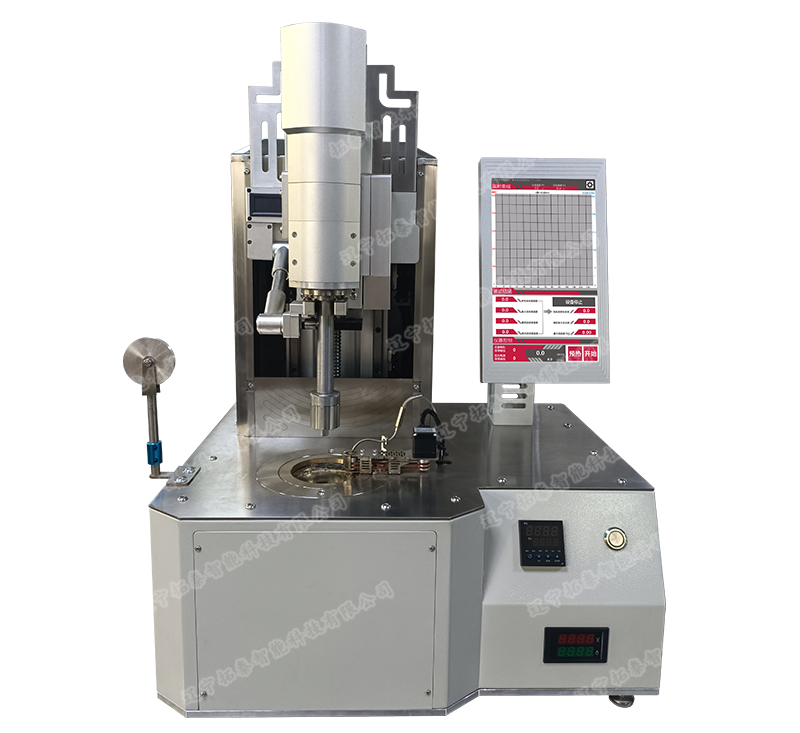

Additional information of bituminous coal constant-torque Gieseler plastometer(2.2)

2024-03-16 17:05Additional information of bituminous coal constant-torque Gieseler plastometer(2.2)

2. Equipment parameter description

This section introduces the technical indicators of several main components of the equipment. If the equipment components do not meet the technical indicators in this section, the real measurement results cannot be accurately obtained!

(1)Retort and crucible: Inner diameter (21.4±0.1) mm; depth (35±0.3) mm; center slot hole φ (2.38±0.02) mm; slope angle 70°

(2)Retort and crucible cover: can be smoothly combined with the retort and crucible! Center hole (9.5 ± 0.1) mm

(3)Guide ring: Material: copper; outer diameter: 13.95 mm; inner diameter: 4.1 mm; height: 9.5 mm

(4)Torque calibration pulley and torque calculation

①Pulley radius: 25.4mm;

②Torque calculation: According to the torque requirements in the national standard (101.6±5.1) g/cm or (0.00996±0.0005) N/M

Torque calculation formula: Torque = force * moment arm;

This equipment is equipped with 3 precision weights, respectively 38g, 40g, and 42g.

Gravity calculation formula: gravity = weight (kg) * gravity coefficient (9.8)

The gravity of a 40g weight is 0.04 (kg) * 9.8 = 0.392N;

The pulley radius is the moment arm of the torque, and the pulley radius is 25.4mm.

So torque = 0.392 (cow) * 0.0254 (m) = 0.0099568 (N/M) ≈ 0.00996N/M.

Regarding ±0.0005N/M, it is calculated from the difference between the 38g weight, the 42g weight and the 40g weight. Torque of 2g difference=0.002*9.8*0.0254=0.00049784 (N/M)≈0.0005N/M;

Regarding the indicator (101.6±5.1) g/cm, g/cm is the simplified unit of torque. After removing the gravity coefficient, the unit is modified to a convenient unit conversion.

The calculation process is as follows:

40g (weight) * 9.8 (gravity coefficient) * 2.54cm (force arm) = 995.68,

And because the unit is g/cm, which is not the unit of expression of force, the gravity coefficient must be eliminated.

995.68÷9.8=101.6g/cm; it can be simply understood as weight * moment arm;

Regarding ±5.1g/cm, in the same way, it is the difference between the weights 2g; 2*2.54=5.08g/cm≈5.1g/cm

(5)Hysteresis device and controller

①Hysteresis device: a device that achieves fixed torque output;

②Controller: A device that accurately controls the torque of the hysteresis device by changing the current supplied to the hysteresis device;

③The meaning of the numerical value displayed on the small screen of the controller: The controller divides the total output power into 255 parts, and the numerical value on the small screen of the controller indicates the power percentage. For example, 100 is displayed on the small screen, indicating that the current hysteresis torque is 100/255 of the maximum torque;

(6)Heating device and temperature control meter

①Heating furnace: 2000W electric furnace wire heating furnace;

②The material in the heating pot: a lead-tin mixture with a total content of 50% lead and a total content of 50% tin;

③Temperature control meter:

(6)Heating device and temperature control meter

①Heating furnace: 2000W electric furnace wire heating furnace;

②The material in the heating pot: a lead-tin mixture with a total content of 50% lead and a total content of 50% tin;

③Temperature control meter:

I: The display on the right side of the machine is the temperature control meter display.

The first row of red numbers represents the temperature measured by the thermocouple, which is the temperature in the tin bath.

The second row of green numbers is the target temperature at this moment, which is the theoretical temperature at this moment at a heating rate of 3°C per minute during the test.

II: There is a problem with the set value on the touch screen and the set value on the temperature control meter.

The set temperature value on the touch screen is the result of data processing for viewing by customers, for comparing the heating effect and drawing the actual temperature and set temperature curves. The set value displayed on the temperature control meter is the temperature set value calculated internally by the temperature control meter and is used as a reference for maintenance personnel.

This instrument uses the catch-up method to heat up. The catch-up method means that the actual temperature and the set temperature will always differ by a fixed temperature value.

The test process requires the equipment to have a heating rate of 3°C. The value displayed on the meter is fixedly 4 degrees different from the value displayed on the screen. Because the difference is fixed, it means that the slope of the temperature calibration curve does not change (the heating rate is fixed). In order to facilitate testers to check the temperature rise, the fixed temperature difference is processed through the main control program data, and the 4°C difference is removed, so that the set temperature and the actual temperature are on the same line. So the temperature data we see on the screen is different from the temperature data on the meter. (The temperature difference is fixed at 4°C).

(7)Sample preparation device: The sample preparation device is based on the requirements of the national standard for sample preparation devices: "static load 9KG, dynamic load 1KG, the latter free fall from a height of 115mm 12 times."

Square press weight: 9kg; cylindrical press weight: 1kg; cylindrical press lifting stroke: 115mm;

3. Equipment maintenance instructions

(1)Cleaning of test equipment

①After each test, clean all carbon residue on the crucible and stirring paddle; remove the residue in the exhaust pipe to maintain its original inner diameter; clean the guide ring and drip a small amount of lubricating oil into the guide ring;

②Regularly check whether the thermocouple protection tube is damaged;

(2)Components need to be inspected regularly

①Retort crucible: Check the inner diameter, depth, and positioning holes of the retort crucible for wear. For specific dimensions, see the "Equipment Parameters" section;

The inner diameter, depth, and positioning holes of the retort crucible need to be cleaned after each test. It is easy to change due to wear and tear of cleaning equipment. The specific impacts are as follows:

I: Consequences of expanding the inner diameter and depth: When a fixed-weight coal sample enters the retort crucible, because the inner diameter and depth expand, the height relative to the pulverized coal decreases and the contact area becomes larger. As a result, the pressure endured during sample preparation becomes smaller, resulting in greater fluidity!

II: Wear of the positioning hole: causing the friction force between the stirring paddle and the retort crucible to increase, resulting in low fluidity!

②Stirring paddle size: The stirring paddle is a precision component, and slightly changing the size will have an irregular impact on the fluidity!

③Thermocouple calibration: Thermocouples need to be calibrated or replaced regularly. Temperature has an absolute influence on the coal softening process. Under different heating rates, the coal softening phenomena are completely different. The faster the heating rate, the lower the coal softening temperature.

④Regularly calibrate the output torque: Use the "hanging weight" method to calibrate the torque. It is recommended to calibrate before the experiment every day!

⑤Calibrate the electronic scale regularly: the amount of coal sample has a great impact on the data!

Our company's bituminous coal constant-torque Gieseler plastometer is also called bituminous coal fluidity equipment, bituminous coal Gieseler measuring instrument, bituminous coal Gieseler fluidity equipment. It is divided into bituminous coal single furnace fluidity equipment, bituminous coal double furnace fluidity equipment.