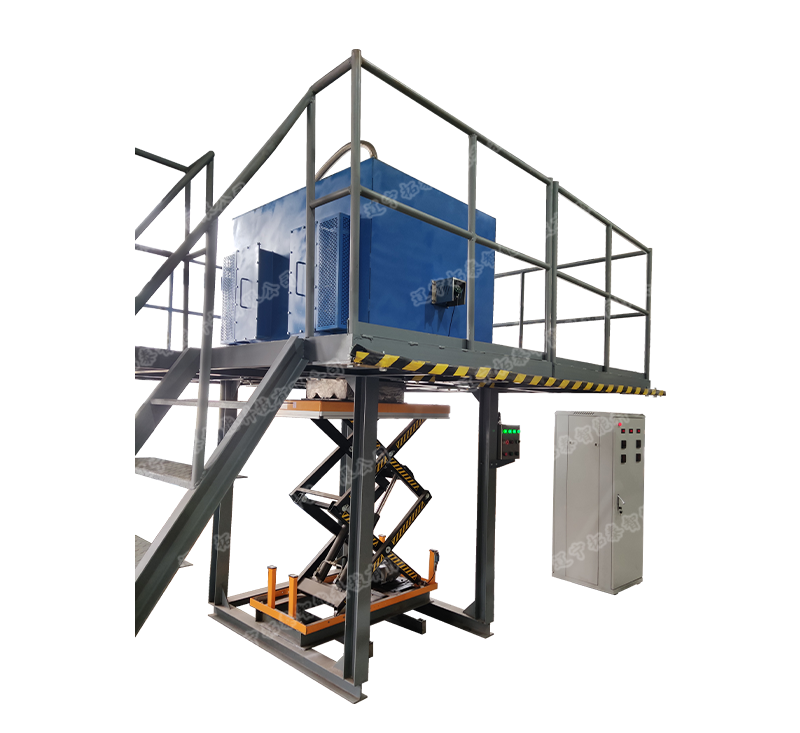

TT-DZ-40KG 40KG bottom-loaded test coke oven

2024-06-06 13:45For thermal strength acceptance of coal entering the factory!

TT-DZ-40KG 40KG bottom-loaded test coke oven

●Product introduction of 40KG bottom-loaded test coke oven

The 40KG bottom-loaded test coke oven produced by our company adopts the method of bottom-loading coal and is equipped with an electro-hydraulic lifting device to realize automatic coal loading and coke removal.

The furnace door opens and closes automatically, with good sealing performance. The furnace door can be quickly closed after coke is discharged, which can effectively extend the service life of the furnace bricks and enable the coke oven to run continuously to prepare for the next furnace. The coal loading trolley can easily load coal and remove coke, reducing manual labor.

The furnace structure simulates the single-hole carbonization chamber of an industrial coke oven. The furnace walls on both sides are heated independently. The furnace walls of the carbonization chamber are made of silicon carbide bricks that are resistant to extreme cold and heat to improve heat transfer efficiency and ensure the sensitivity of temperature regulation.

The heating element is a silicon carbon rod, which is arranged on both sides of the furnace wall. The control program executed by the computer controls the temperature of the furnace walls on both sides individually to improve the temperature control accuracy. The core temperature of the coke cake and the temperature of the furnace walls on both sides are collected by the thermocouple and displayed and recorded by the computer.

The test coke oven is also equipped with a coke oven gas combustion treatment system to ensure that coke oven gas emissions meet environmental protection requirements.

●Usage of 40KG bottom-loaded test coke oven equipment

Analyze the coke yield, thermal strength index (CRI, CSR) of coal blending or single coal, and conduct experimental research on conventional and tamping coking. Provide experimental research data for rational utilization of coal resources and improvement of coke product quality to guide and improve production. We can also explore suitable coal blending conditions based on the thermal intensity index of coke generation, infer the economy and possibility of production, and provide materials for the rational utilization of coal resources.

Our company's production includes:automatic intelligent coal coke petrographic analysis system, simulated pressurized coke oven, measuring device for coke reactivity and post-reaction strength, bituminous coal colloidal layer measuring instrument,bituminous coal constant-torque Gieseler plastometer, including dozens of various coal rocks, coal quality, coke and iron pre-inspection equipment.