Automatic Dust Removal Device For Belt Conveying Coal Ash

●Automatic dust removal device for belt conveying coal ash, novel in design, reasonable in structure and high in technical content. No manual operation is required, and the dust removal effect is remarkable.

●The automatic dust removal device for belt conveying coal ash has good effect and meets the national standard of "hygienic respirable dust in the air in the workplace".

●Automatic dust removal device for belt conveying coal ash, our company has a complete after-sales service system to provide satisfactory after-sales service for all customers.

- Liaoning Tuotai

- Anshan City, Liaoning Province, China

- Information

Our company sincerely recruits agents from all over the world, and you are welcome to contact us if you are interested in cooperation. +86-15642202798.

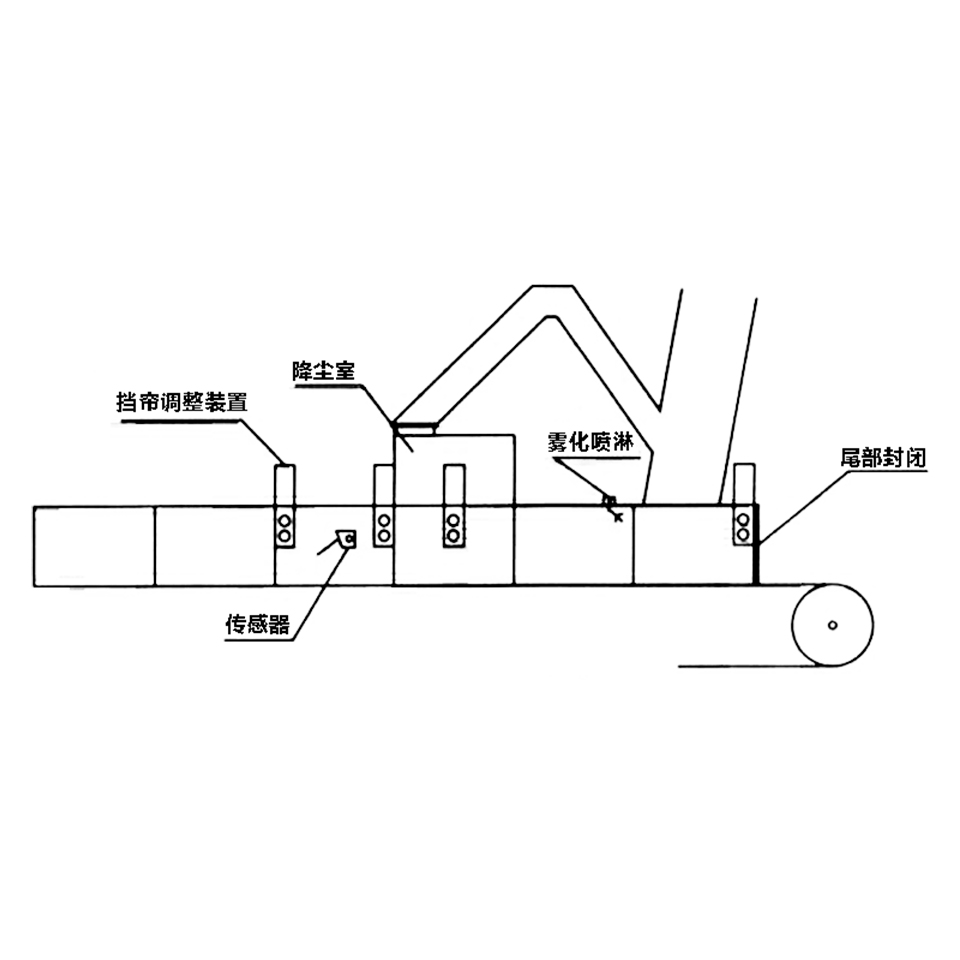

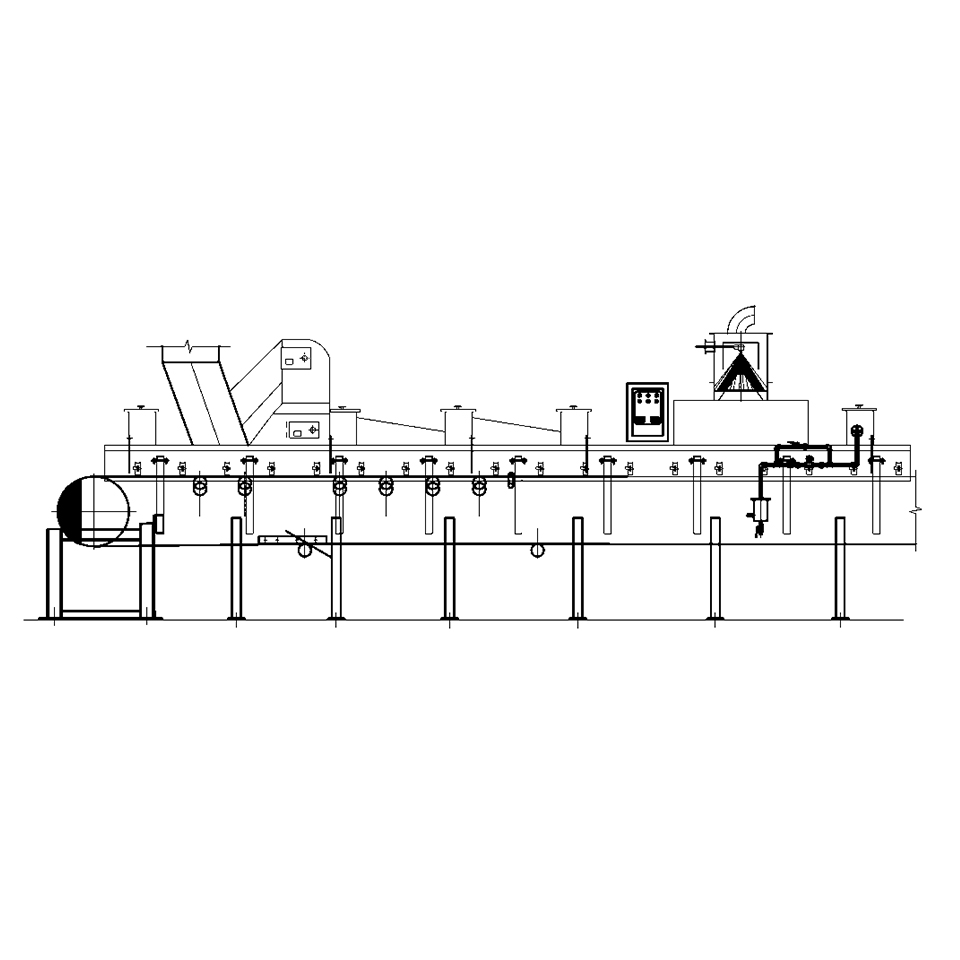

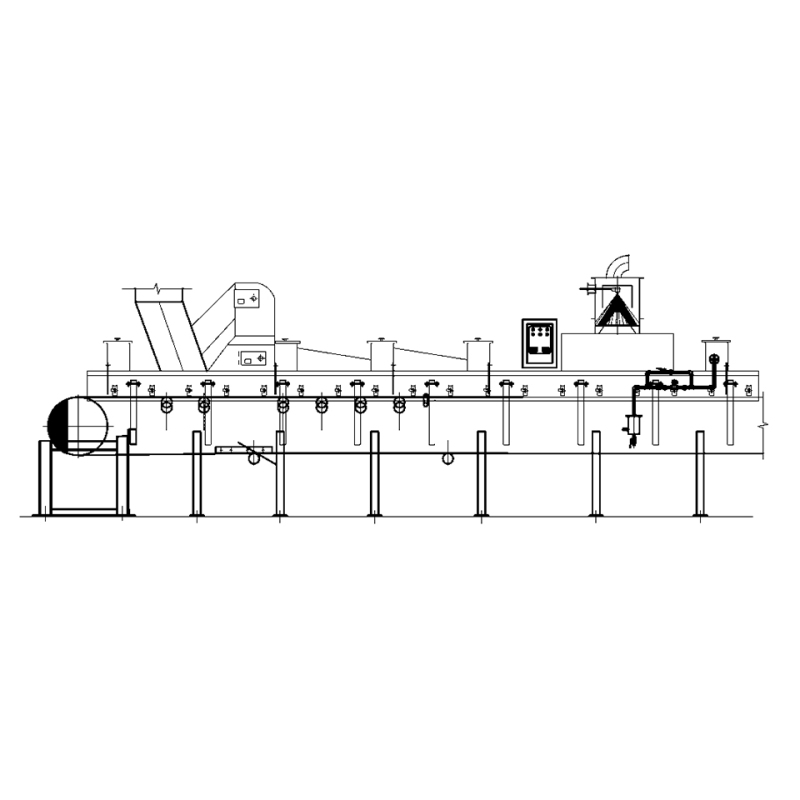

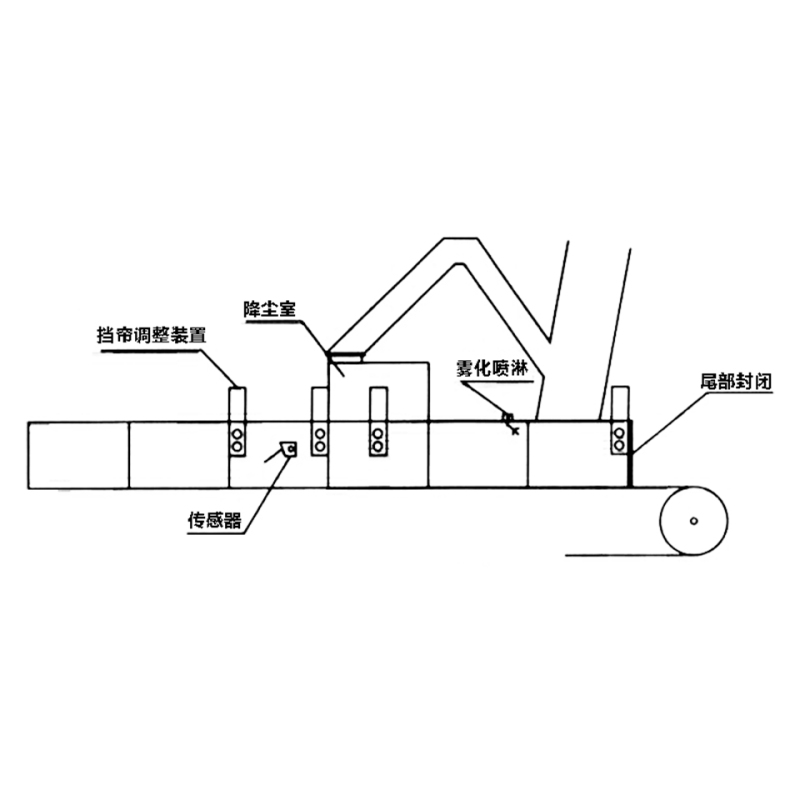

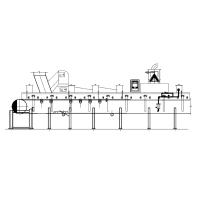

●Introduction to the technology of automatic dust removal device for belt conveying coal ash

It is designed according to the actual situation of dust generated by conveying materials in thermal power plants, mines, metallurgy and ports.

This product adopts the primary and secondary negative pressure dust removal device, which is in line with the basic laws of physics, with novel design, reasonable structure, high technical content, remarkable dust removal effect, no secondary pollution, no need for electromechanical power, and no need for frequent maintenance. Device transcendence.

In order to control the humidity of the material and the amount of dust generated, an automatic control system for dust suppression and humidity is adopted. When the material is dry and produces a large amount of dust (generally, the external moisture content of the material is less than 9%), the controller outputs an execution signal to implement wetting. When the moisture contained in the material is not easy to generate dust (generally when the moisture contained in the external load is above 10%), the control system will automatically cut off the power supply and end the wetting work.

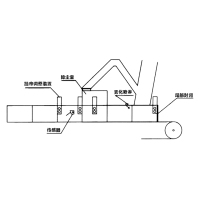

●Working principle of automatic dust removal device for belt conveying coal ash

Mainly adopt the concept of dust removal with primary and secondary negative pressure devices. Negative and positive pressure alternate cycles are realized under negative pressure. During the conversion process of belt transportation, the impact dust generated is fully released in the multi-functional dust removal device, and the circulation and impact can be accelerated, so that the gas pressure can be fully utilized to achieve the purpose of dust removal.

In order to ensure the good functional characteristics of the multi-functional dust removal device, all places in contact with the movable belt are equipped with sealing and adsorption facilities to achieve the effect of eliminating dust from overflowing and achieving the goal of dust removal.

●Performance characteristics of automatic dust removal device for belt conveying coal ash

1. Novel design, reasonable structure and high technical content;

2. Without manual operation, the dust removal effect is remarkable;

3. Less investment, only occupying the space above the belt, basically no maintenance;

4. No secondary pollution, the dust will fall back on the material and be transported away after dust removal;

5. Unique warehouse structure, coated with wear-resistant and corrosion-resistant coating;

6. Unique sealed dust removal soft curtain designed for different dust;

7. The effect is good, reaching the national "hygiene of respirable dust in the air of the workplace" standard.