Several "bugs" in coal coke petrographic analysis instrument procurement.

2023-10-07 13:42Several "bugs" in coal coke petrographic analysis instrument procurement.

1. Pay attention to the so-called "imported brands or authoritative institutions" and ignore "actual combat performance".

Liaoning Tuotai's coal and rock technology comes from more than 60 years of technical precipitation, and nearly 400 domestic users are using it. The effect is far better than that of some so-called "German imported brands" or newly developed products by "a certain authoritative department"; Liaoning Tuotai has almost transformed all brand equipment on the market, but has never been transformed by other companies.

2. Pay attention to the "microscope" and ignore the "measurement and control system".

The most important thing about the automatic intelligent coal coke petrographic analysis system is the "measurement and control system", not the microscope. Even "making samples and grinding samples" is more important than microscopes. Ranking of importance: measurement and control system>making samples, grinding samples>microscope. All in all: an easy-to-use measurement and control system, even if it is installed on the world's lowest-end microscope, the data is still accurate. On the contrary, if the measurement and control system is not easy to use, even if it is installed on the best microscope in the world, the data will be inaccurate.

3. Is the core "recognition algorithm" accurate? Has it been tested in practice?

In addition to manual sample testing, as long as you want to use automated coal and rock, the core of whether the data is accurate is the "identification algorithm". However, users cannot tell the difference. Each company has its own patented technology, and the bidding conditions cannot be marked out. Therefore, as an end user, you can only rely on "performance quantity and usage effects" to "assist in judging" whether it is good or bad.

4. Is it "manual" or "automatic"?

"Manual retouching" and "manual focusing" are not automatic. In practice, the results are not good; there are two major shortcomings of the image editing method:

① Slow speed: full repair takes more than 1 hour; for "partial" repair of the histogram, there is a problem of "only subtraction, not addition". The corresponding data of the unrecognized image in the process will not appear in the final result On the histogram, you can't fix it even if you want to. The revised results are still inaccurate;

②Accuracy depends on the experience of the laboratory technician; one person will fix the result.

5. Using "cheap" as "expensive"

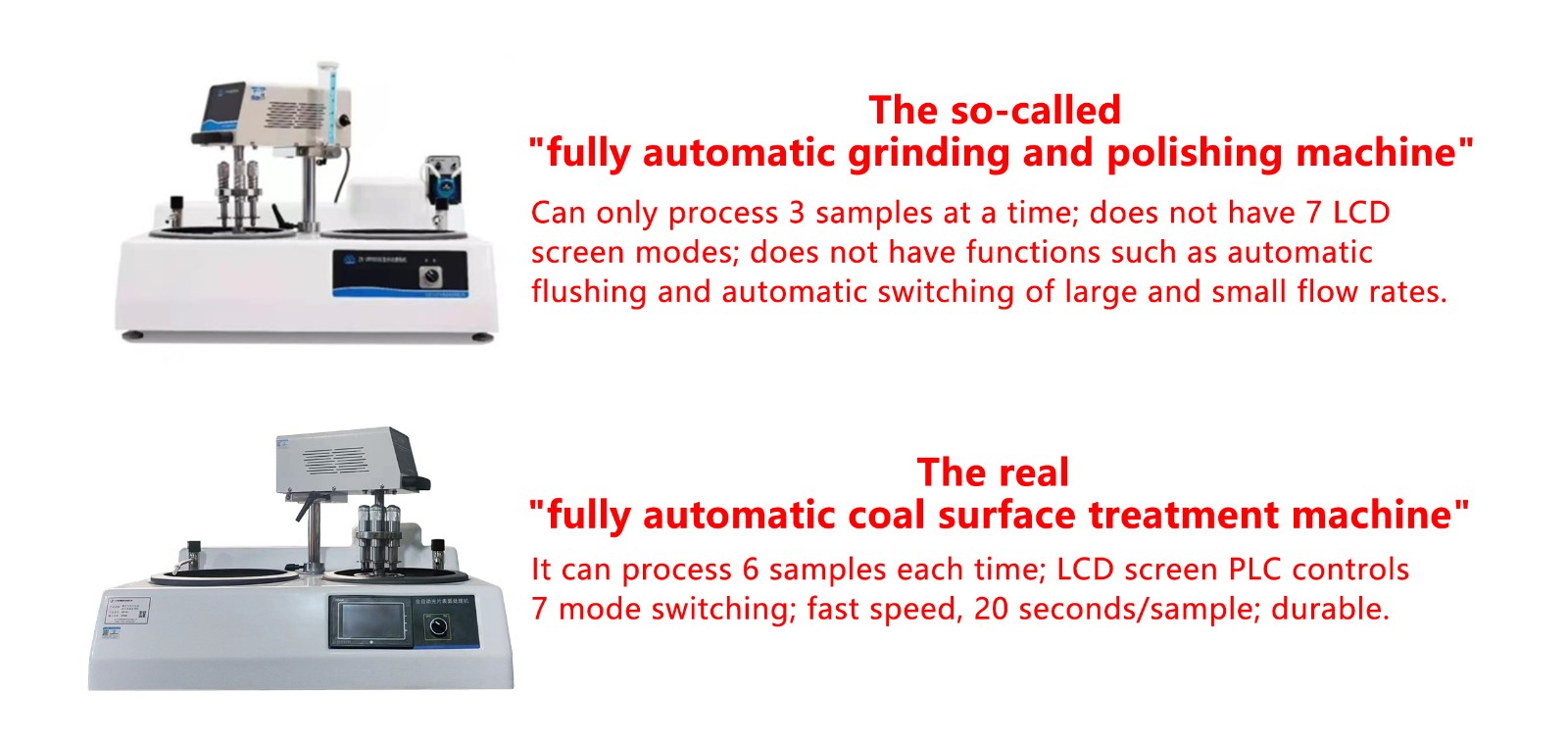

The difference between the so-called "automatic grinding machine" and the real "light sheet surface treatment machine for coal".The price difference is more than 50,000.

The so-called "fully automatic grinding and polishing machine": Can only process 3 samples at a time; does not have 7 LCD screen modes; does not have functions such as automatic flushing and automatic switching of large and small flow rates.

The real " fully automatic coal surface treatment machine": It can process 6 samples each time; LCD screen PLC controls 7 mode switching; fast speed, 20 seconds/sample; durable.

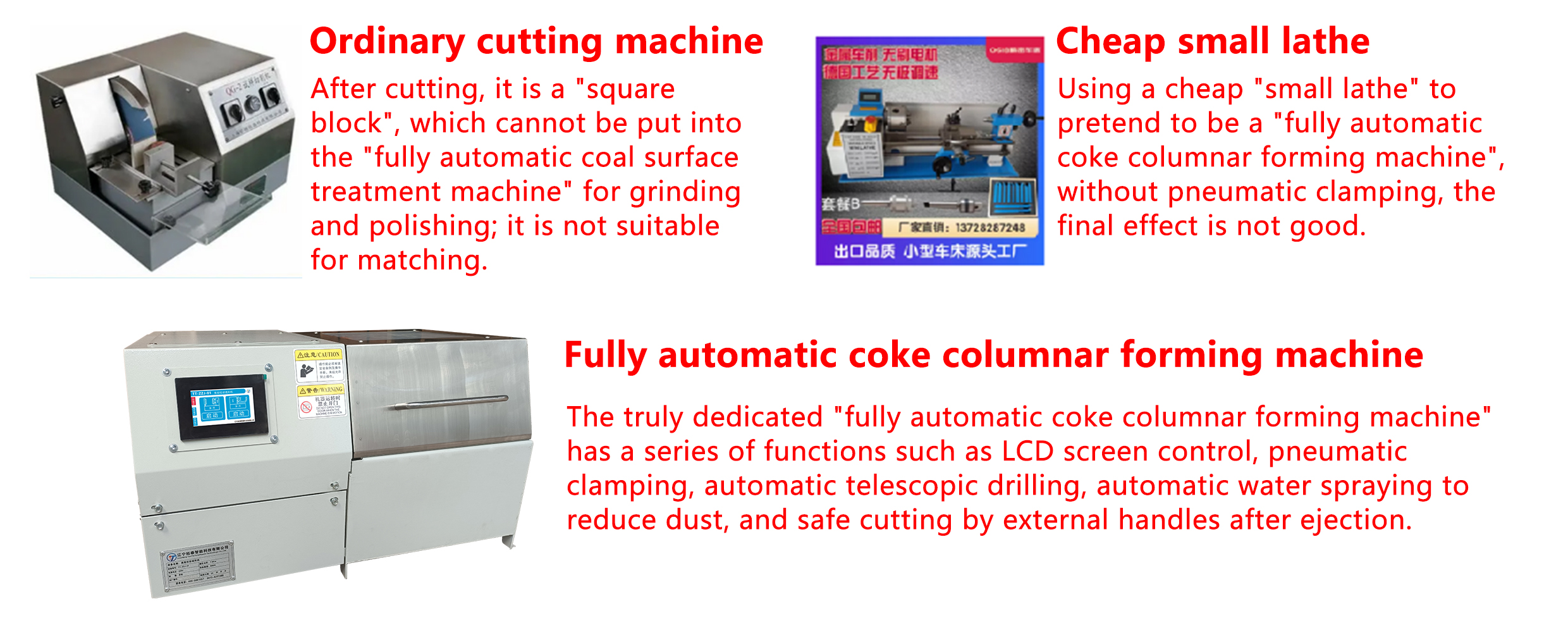

The difference between "ordinary cutting machine" or "small lathe" and "coke column forming machine"; the price difference is more than 50,000;

After cutting, it is a "square block", which cannot be put into the "fully automatic coal surface treatment machine" for grinding and polishing; it is not suitable for matching.

Using a cheap "small lathe" to pretend to be a " fully automatic coke columnar forming machine", without pneumatic clamping, the final effect is not good.

The truly dedicated "fully automatic coke columnar forming machine" has a series of functions such as LCD screen control, pneumatic clamping, automatic telescopic drilling, automatic water spraying to reduce dust, and safe cutting by external handles after ejection.

6. The so-called lens magnification issue that complies with the “new national standard”.

There is no other way in the competition, just use "50x oil immersion" as a layman's term.

In fact, the CMOS or CCD detector used in the image method has only "a few micron levels" per pixel unit. Even if the microscope magnification digit is 0, it still complies with the requirement that the "detection area does not exceed 10 microns in diameter"; and it is the user's choice to match 20x or 50x. There is no such thing as saying that any equipment manufacturer can only match 20x but cannot match 50x. It is purely a layman's term that does not understand.